Attachment compactor V10

Recommended excavator size: 21 to 45t

The V10 attachment compactor is our powerful heavyweight with absolute efficiency. The extremely robust unit achieves maximum compaction performance within seconds. It is suitable for all excavator classes from 21 to 45 tons and is optionally available as a WA compactor.

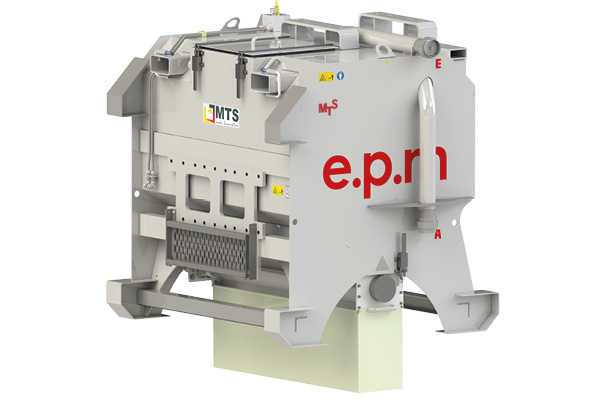

e.p.m binding agent spreader

Recommended excavator size: 10-30t

Recommended wheel loader size: 5-12t

The e.p.m binding agent spreader developed by MTS is coupled to an excavator or loader and is filled with the corresponding binding agent. The first step is to distribute the binding agent dosed on the excavation material. Dosing takes place via a hydraulic drive, the binding agent level is visually displayed. The binding agent level can be correspondingly adjusted to the respective soil conditions here by means of the binding agent spreader. The binding agent-soil mixture is then mixed homogeneously with a crusher in a single step and fitted in the pit during the same process where possible. Thanks to the hydraulic quick-change unit, the binding agent spreader for the excavator is always at your fingertips, thus reducing the relevant downtimes to a minimum.

with a capacity of 1.4 m³, it is possible to accommodate a BigBag without any problems

(Kopie 2)

precise monitoring

Dust-free dispensing of the binding agent

Continuously variable dosing of the binder level

with filter bag

Secure footing for maintenance and operation

Filling via stand silo or BigBag

Easy to clean thanks to hinged closure

e.p.m box with eye wash bottle, protective goggles, protective gloves and breathing mask

various transport options, e.g. via wheel loader with forklift truck

Simple coupling for quick-change adapter (loader)

Sie sind auf der Suche nach einem passenden Anbaugerät in Ihrer Baggerklasse?

e.p.m binding agent spreader

| Model designation | e.p.m 1102 |

| Filling quantity [m³] | 1,40 |

| Weight [kg] without plate | 840 |

| Hydr. recommendation [l/min] | 25-40 |

| Output minimum (kg/min) | 250 |

| Binding agent silo | 22 or 29m³ | Capacity (incl. internal filling pipe and impact absorber) Pipe screw conveyor | 36 m³/h | Conveying capacity (length: 3,700mm) compressed air filling system | for silo | (incl. filling hose and pressure hose) |

Why soil improvement?

Soil is a useful construction material and induces high costs during conventional replacement procedures. Modern soil conditioning methods, which are consistent with the applicable guidelines for earthwork and road construction (ZTVE-StB 17), are cost-efficient – especially since the replacement of soils in any case contradicts the Recycling and Waste Management Act. Since the replacement of upcoming soils is usually insufficient, however, due to lack of compressibility, poor load capacity or large stone deposits, it is important to optimize these properties through soil conditioning measures. The focus here is on the reduction of the water content and the structural improvement of the soil. The process that has been developed by MTS for this purpose, which is both cost-efficient and resource-friendly, is called e.p.m.

How does e.p.m work?

Quite simple: The binding agent spreader is coupled to an excavator or loader and is filled with the corresponding binding agent. The first step is to distribute the binding agent dosed on the excavation material. Dosing takes place via a hydraulic drive, the binding agent level is visually displayed. The binding agent level can be correspondingly adjusted to the respective soil conditions here by means of the binding agent spreader. The binding agent-soil mixture is then mixed homogeneously with a soil recycler in a single step and fitted in the pit during the same process where possible. Thanks to the hydraulic quick-change unit, the binding agent spreader for the excavator is always at your fingertips, thus reducing the relevant downtimes to a minimum.

Which application areas are useful?

Whether "mixed in place" or "mixed in plant": Due to the easy handling, high performance and faultless results, the e.p.m procedure can be used in underground engineering within city limits as well as large development measures. Since grain fractions of 20 to 110 mm can be obtained by means of a specially designed soil recycler, the e.p.m procedure also facilitates use in the pipeline area according to DIN EN 1610.

Which binding agent?

Depending on the task and the soils in question, the most appropriate binding agent must be established to begin with. For clayey and strongly binding soils, we recommend binding agents with a high lime (CaO) content. For coarse and mixed-grained soils, we recommend binding agents with higher cement content. Since soil properties frequently change in their composition within a construction site, a mixed binding agent is often recommended.

How do binding agents work?

Caustic lime binding agents (chalk CaO DIN 1060), which primarily consist of calcium oxide and magnesium oxide and are produced through the burning of carbonate rocks, react with water in the soil by producing heat and then dry the soil.<br/> Cement-containing binding agents increase the bearing capacity of the soil through cementation of the granular structure.<br/> Mixed binding agents are factory-made mixtures consisting of building limes and cements (with the addition of fillers if necessary). They reduce the water content and increase the bearing capacity as a result.<br/> Mixed binding agents containing CaO cause:<br/> => crumb formation<br/> => reduction of water content<br/> => lessening of plasticity<br/> => improvement of compactability<br/> => increase of load-bearing capacity<br/> => increase of frost resistance (>3 wt.-% addition)<br/> => shifting of the Proctor curve to the "wet side"

Which binding agent level?

The binding agent level depends on the respective soil properties and the weather conditions. If the soil is conditioned and embedded into place immediately after excavation within the e.p.m procedure, then rain or water content cannot have any negative influences. Experience has shown therefore that stiffer soils can be processed during soil conditioning at 1 % (weight %) on average.<br/>

MTS product portfolio 2018

MTS binding agent spreader